General information:

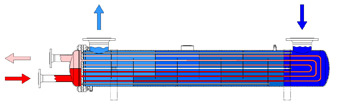

Tube bundle heat exchangers make it possible to exchange heat between

two media whenever a temperature differential exists between them.

This is achieved by allowing the media to flow past each other. They

are separated by the tube wall.

In a tube bundle heat exchanger, one medium flows through the tubes and

the other medium flows through the shell space. The shell space contains

devices known as baffles which on the one hand divert the medium flowing

in the shell space to the tube bundles and on the other hand prevent

the inner tubes from vibrating.

In tube bundle heat exchangers the space inside the tubes is designed

to be either unidirectional or multidirectional. This depends on the

speed and the pressure drop of the medium flowing through the tubes.

Tube bundle heat exchangers may be employed both as coolers and as heaters

for fluid or gasiform media.

Models:

AAN makes three different models of tube bundle heat exchangers which

are designed for either horizontal or vertical use. We select the most

appropriate design in accordance with the operating conditions.

Types WK and W

Manufactured sizes:

- Type WK with an outer shell diameter of between 88.9 and 139.7 mm

- Type W with an outer shell diameter of between 168.3 and 812.8 mm

Characteristics:

- screwable chambers

- extractable tube bundle (facilitates cleaning)

- longitudinal expansion of the tubes caused by heat is compensated by the moveable tube plate

- straight tube bundle without profiling

Operating conditions:

- temperatures of up to 160 ºC

- pressures of up to 10 bar

Applications:

- tempering baths

- industrial washing machines

- oil coolers

Materials:

- stainless steel

- steel

- interior of tubes made from non-ferrous metals (copper, brass)

Types FPK and FP

Manufactured sizes:

- Type FPK with an outer shell diameter of between 88.9 and 139.7 mm

- Type FP with an outer shell diameter of between 168.3 and 812.8 mm

Characteristics:

- screwable chambers

- fixed tube bundle

- longitudinal expansion of the tubes caused by heat is absorbed by the compensator built inside the shell

- straight tube bundle without profiling

Operating conditions:

- temperatures of up to 600 ºC

- pressures of up to 10 bar

Applications:

- gas coolers

- condensers

- wort boilers

Materials:

- stainless steel

- steel

- interior of tubes made from non-ferrous metals (copper, brass)

Types UK and U

Manufactured sizes:

- Type UK with an outer shell diameter of between 114.3 and 139.7 mm

- Type U with an outer shell diameter of between 168.3 and 812.8 mm

Characteristics:

- screwable chambers

- extractable tube bundle (facilitates cleaning)

- longitudinal expansion of the tubes caused by heat is absorbed

- U-form tube bundle without profiling

Operating conditions:

- temperatures of up to 200 ºC

- pressures of up to 16 bar

Applications:

- vapour heaters

- condensers

Materials:

- stainless steel

- steel

Note:

By clicking ‘Downloads’ you can obtain the dimension

sheets of AAN standard heat exchangers. Special equipment tailor-made

for specific applications can be ordered at any time.