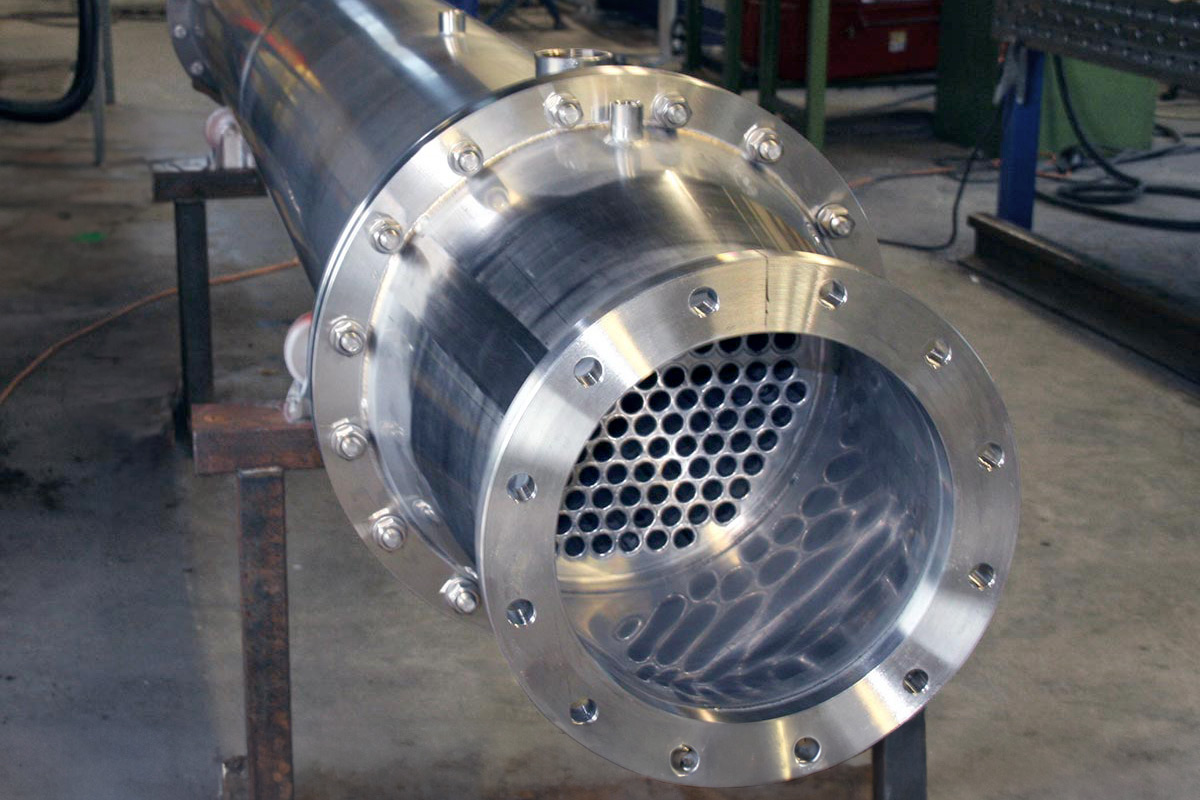

A tube bundle heat exchanger makes it possible to exchange heat between two media when there is a temperature difference between them. The two media are guided past each other, separated by the tube wall. In a tube bundle heat exchanger, one medium flows through the tubes, while the other flows through the shell space.

In the shell space, so-called baffles are installed, which direct the medium flowing through the shell space crosswise to the tube bundle, and also prevent the inner tubes from vibrating. In tube bundle heat exchangers, the tube space can be executed as one-way or multi-way. The speed and pressure loss of the medium flowing through the tubes are crucial factors here.

A tube bundle heat exchanger can be used both as a cooler and as a heater for liquid or gaseous media.

In the „Downloads“ section, you will find the data sheets for AAN standard heat exchangers. Custom-made special apparatus tailored to specific applications are always possible.

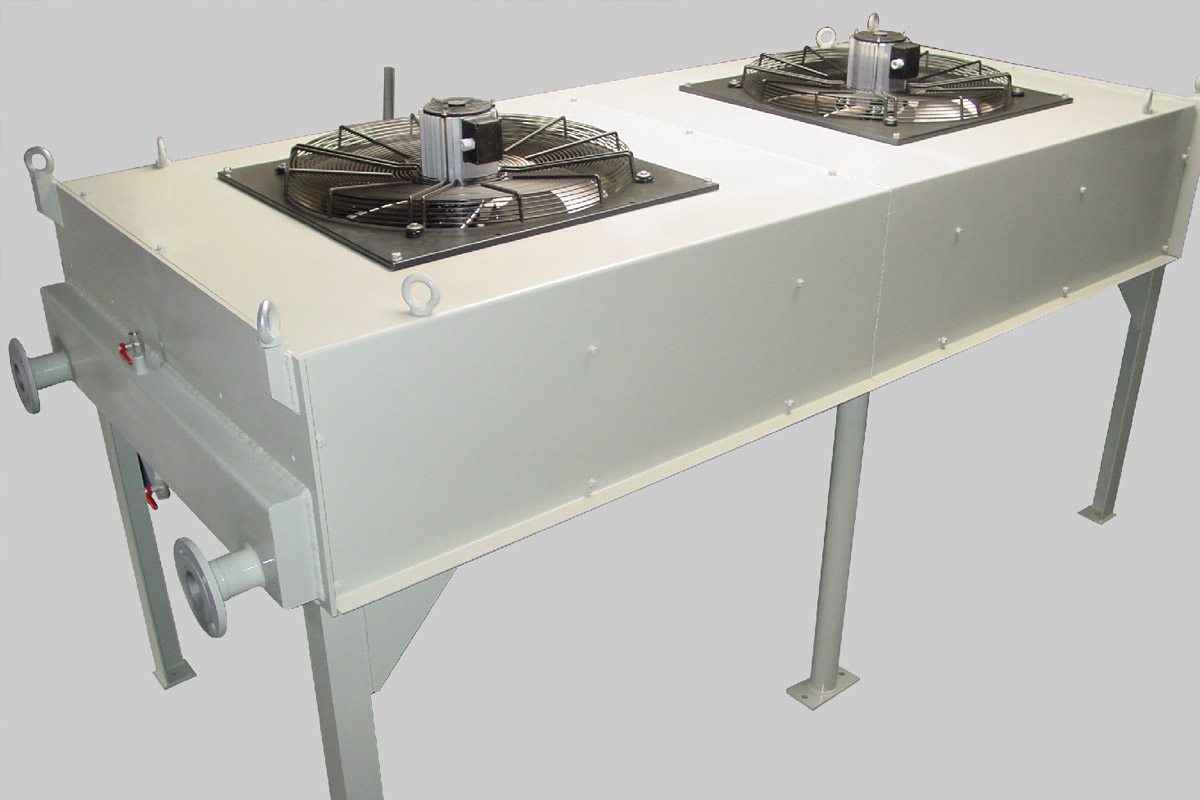

In a liquid cooler, the warm liquid medium is cooled in the tubes using colder ambient air. Due to the lower heat transfer on the air side, the surface of the smooth tube is enlarged by fins. Depending on the flow rate and pressure loss, a one-way or multi-way design is chosen. Heat dissipation is achieved using quiet axial fans.

In the „Downloads“ section, you will find the data sheets for AAN standard heat exchangers. Custom-made special apparatus tailored to specific applications are always possible.

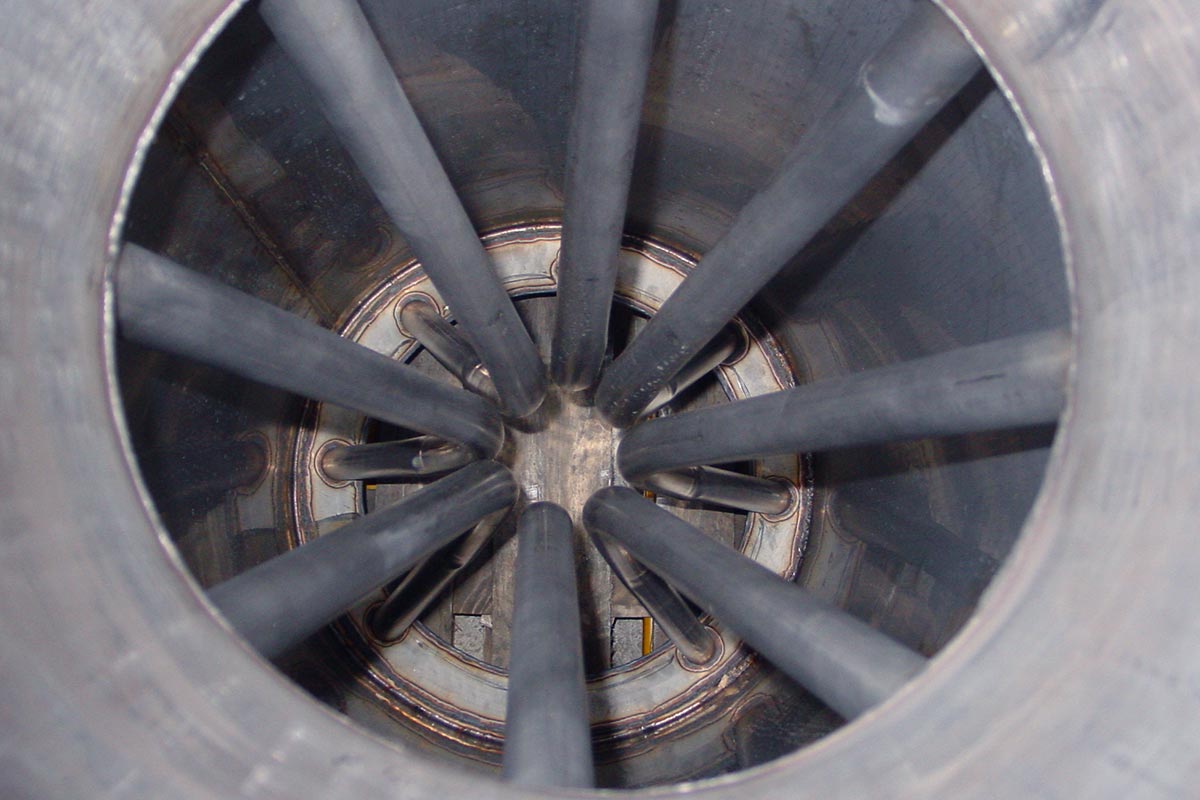

In addition to standard heat exchangers, we design and manufacture apparatus for customer-specific applications.

Applications:

For direct installation in hardening vessels, we produce circulation units, as well as cooling and circulation units for water and polymer quenching media. For special applications in salt bath hardening, we supply circulation units as well as aircooled cooling and circulation units for martensitic and bainitic baths.